In my line of work as a product designer, I often have to deal with gaps and distances that are smaller than 1mm – as much as it may seem diminutive, they really do make a difference in certain applications – like the clearance between the buttons and the main housings, the fit between parts, etc. When dealing in 3d files, tolerances often go to 3 or 4 decimal places of a millimeter for it to work properly.

But that, to a chip engineer, is probably like a blue whale to a mouse. As electronic product races to be smaller and more powerful, they’d have to device ways to lay circuits and build paths around a tiny piece of real estate. And though we do hear a lot about nanotechnology and how it may change the future of production and medicine, sometimes a sense of perspective and scale would be in order to really grasp the “tiny-ness” of it all.

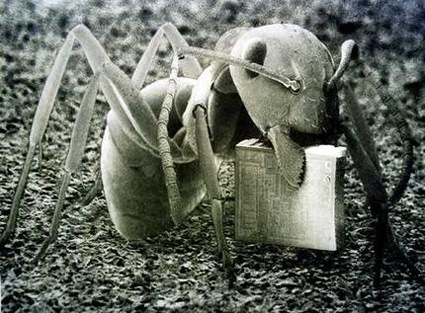

The ant in the picture is holding a IC chip in its mandibles – the chip is just 1mm x 1mm. That would really put some perspective into the scheme of things!